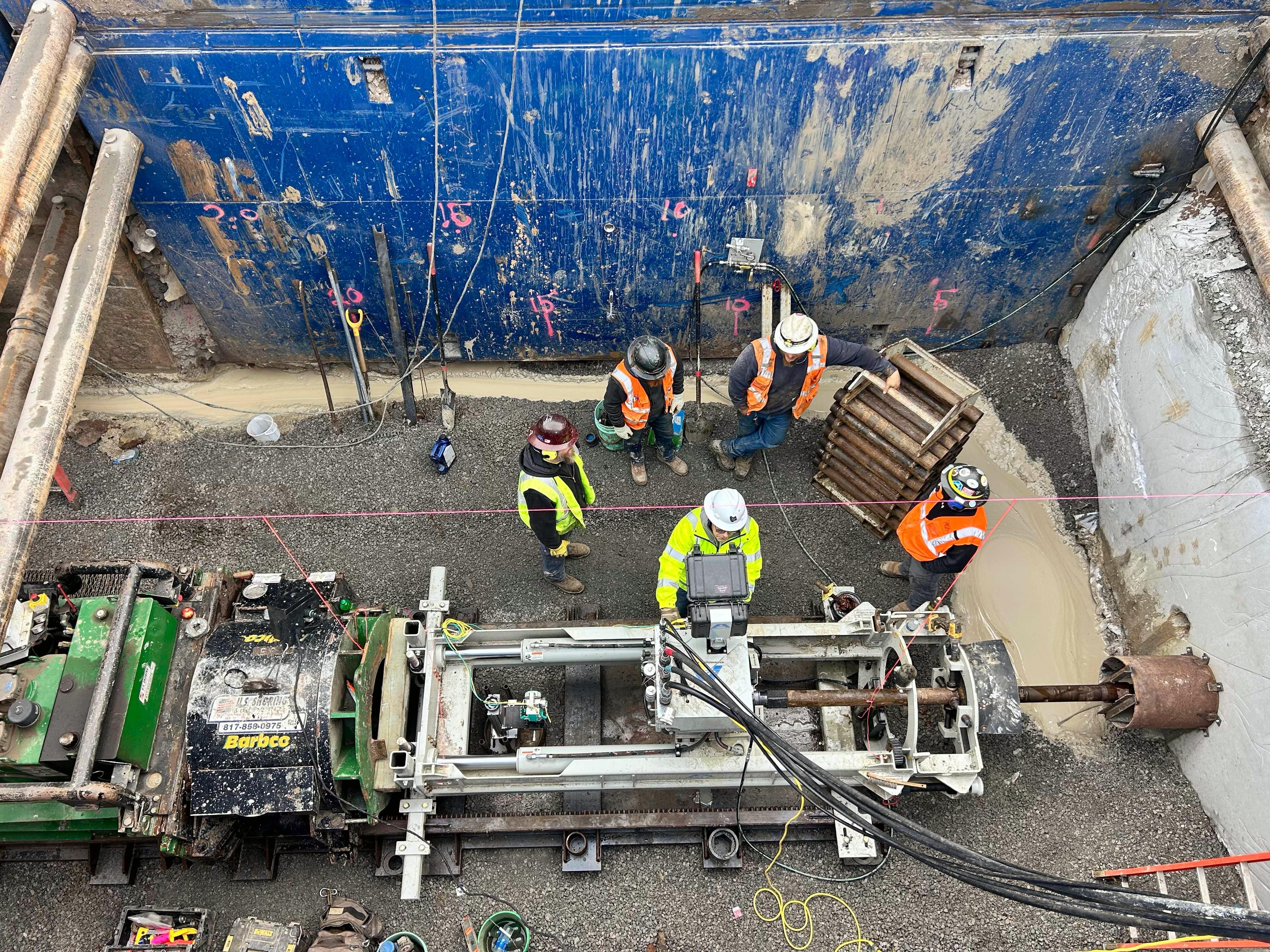

How It Works

Microtunneling is a safe, highly precise trenchless solution perfect for deep or sensitive pipeline installations from a few hundred feet to over one thousand feet. Using a remotely operated tunnel boring machine (MTBM) and pipe jacking techniques, combined with slurry earth-balance control, microtunneling installations allow efficient installation of a variety of pipe types over substantial distances, maintaining precise control over line and grade. This process is ideal for projects requiring minimal surface disruption and exact alignment, such as urban infrastructure, utility crossings, and environmentally sensitive areas.

Benefits

- High precision – typically achieves tight tolerances within a few millimeters using laser or gyro guidance even under deep or long-range installations.

- Increased safety – operators remain on the surface; no human entry into tunnel.

- Ground control – slurry balance manages groundwater and earth pressures, reducing settlement.

- Versatile in challenging soils – effective in varied strata, including soft soils, mixed-face, and high groundwater level geology.

- Capable of longer drives and larger diameters than conventional auger boring—making it ideal for large sewer or pressure main installations.

Applications & Technical Details

- Common applications: ideal for installing sewer, water, storm, gas, electrical, and telecom pipelines—especially under roads, rails, buildings, and environmentally sensitive areas.

- Pipe Types: Microtunneling accommodates a range of jacking-ready pipes installed directly behind the MTBM, with optional segmental lining, selected based on project requirements and ground conditions:

- Reinforced Concrete Pipe (RCP): Commonly used for gravity sewer installations due to its rigidity and ability to withstand jacking forces.

- Steel Casing: Preferred for installations requiring additional structural protection or for pressurized pipelines in demanding environments.

- HOBAS, FRP, CCFRM): Occasionally used for pressure applications where corrosion resistance and strength are required.

- Polyvinyl Chloride (PVC) & High-Density Polyethylene (HDPE): Typically used as internal carrier pipes within a casing, offering chemical resistance and flexibility.

- Pipe diameters: typically range from 12 in to over 120 in, giving microtunneling the flexibility to handle a wide variety of utility types and capabilities.

- Drive lengths: Typical drive lengths for microtunneling range from 300 to 1,500 feet per segment. However, with appropriate planning and the use of intermediate jacking stations, much longer distances can be achieved. These extended drives allow for fewer shafts and reduced surface impact over large areas.

- Technical components & extras:

- Jacking frame in launch pit provides thrust; interjacks may be used mid‑bore to manage friction loads.

- Slurry system maintains face pressure and transports spoil back to separation plant on surface.

- Guidance systems (laser or gyro) track MTBM’s position, ensuring precision.

- Remotely controlled – surface operation from a control panel ensures operator safety.

- Continuous pipe installation as MTBM advances, reducing construction time and risk of collapse.

Advantages

- High Precision: Maintains tight tolerances on line and grade, even over long distances or at deep depths.

- Minimal Surface Disruption: Ideal for congested or environmentally sensitive areas where traditional excavation would be intrusive or infeasible.

- Versatile Across Soil Conditions: Capable of handling soft ground, flowing soils, and mixed face conditions with the appropriate MTBM configuration.

- Supports Large Diameters and Long Drives: Enables the installation of large-diameter pipelines over extended lengths with fewer intermediate access points.

- Remote Operation Enhances Safety: Operators remain at the surface, reducing exposure to confined spaces and underground hazards.